Overview

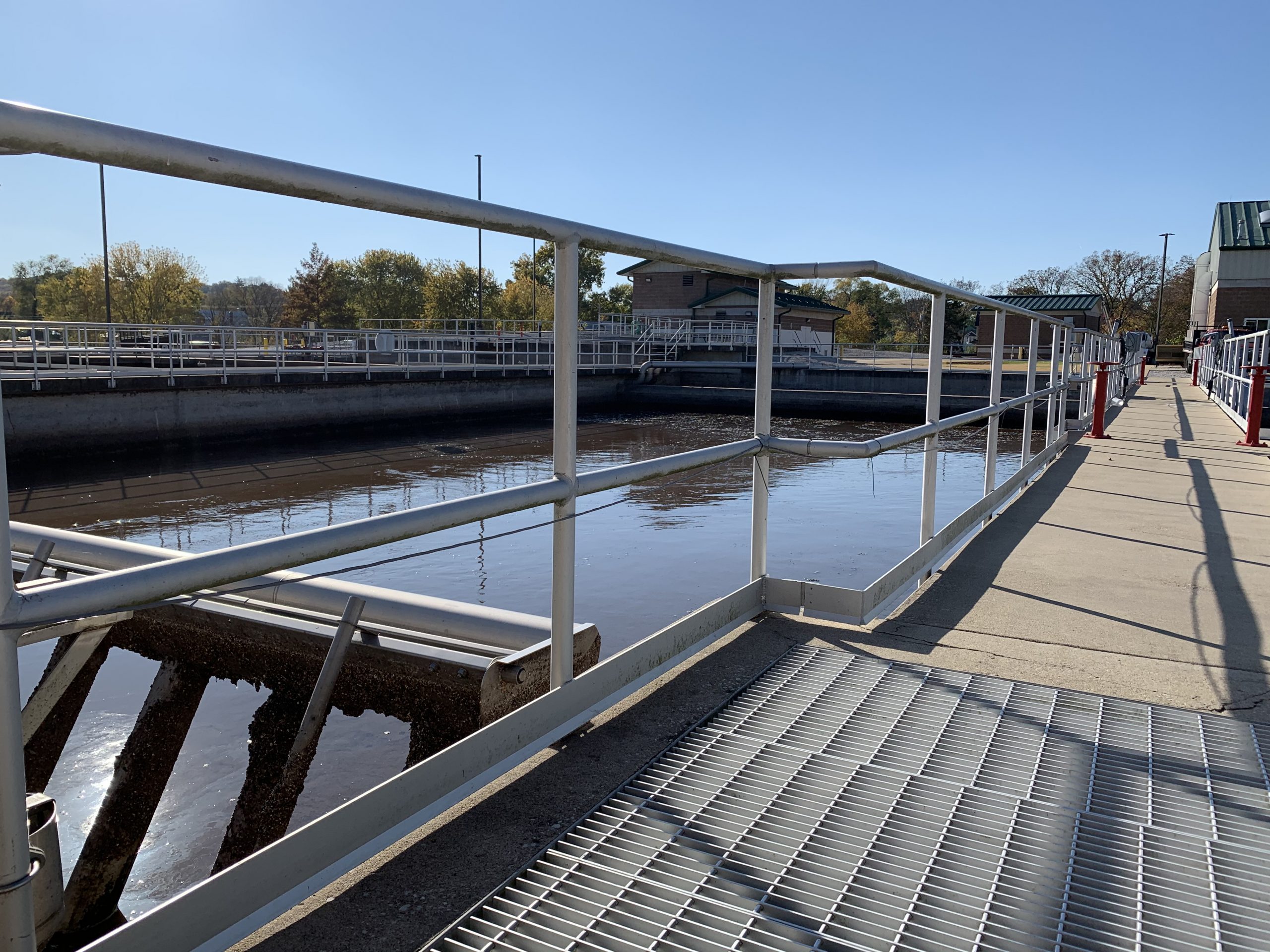

Horner & Shifrin provided professional engineering services to the City of Jackson, MO to evaluate the condition and functionality of the existing wastewater treatment system and investigate the most economic and constructable options to maintain, improve, and meet future capacity and regulatory requirements. H&S prepared and submitted a Facility Plan Update to the Missouri Department of Natural Resources along with assisting the City with application for SRF funding. Currently H&S is designing nine recommended improvements for the WWTP.

The current treatment plant has existing hydraulic capacity to meet flow projections through the 20-year planning period; however, replacement of the brush rotors with a new disk aeration system in the existing oxidation ditches will be required for the organic treatment capacity to meet projected organic loadings in this time period. This process upgrade will reduce plant energy consumption. In addition, the decanting thickening procedure in the aerobic digesters was determined to be the major existing choke point in the process. A membrane thickening aerobic digestion process is recommended to provide in-situ thickening while continuing aeration. The process uses no chemicals, minimal equipment and energy compared to mechanical thickening. The recommended project will ease stress on the blowers from constant on/off operation as well as increase hydraulic residence time as directly applicable to SOUR testing.

The wastewater treatment plant projects include:

– Sludge Treatment Upgrade – Install MEMTAD thickening system. Accomplishes sludge thickening w/o use of chemicals or mechanical equipment.

– Screen Building Modifications – Update the influent screen building to be compliant with NFPA Class I Div I area.

– Administration (Control) Building – Construct a new control building, and expand electrical room in existing building.

– Plant SCADA – Implement a plant SCADA system for data acquisition and remote monitoring of process parameters.

– Plant Structural Rehab – Execute structural recommendations for treatment units and bring facility up to code.

– Oxidation Ditch Basic Upgrade – Execute aeration system upgrade to Orbal disk system. New system will reduce plant energy consumption.

– Screw Pump Rehab – Replace the worn flights on the existing screw pumps. This reduces energy consumption through screw restoration.

– Splitter Box Weir – Install a new weir in the existing box.

– Clarifier Rehabilitation – Install Full Radius Scum Beaches in the clarifiers, rehab rake mechanisms, replace telescoping valves, modify scum removal