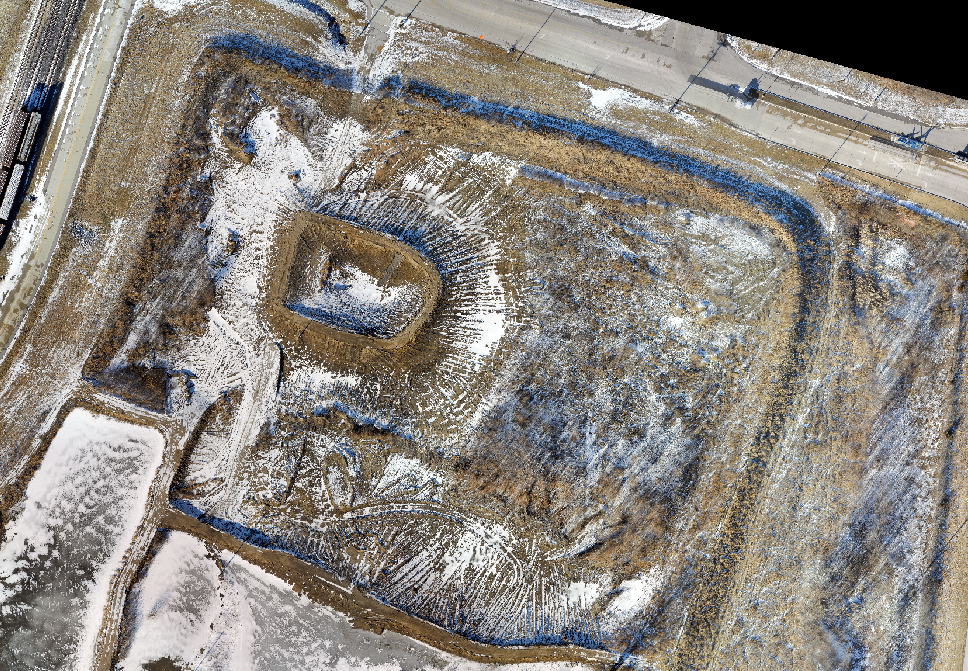

Overview

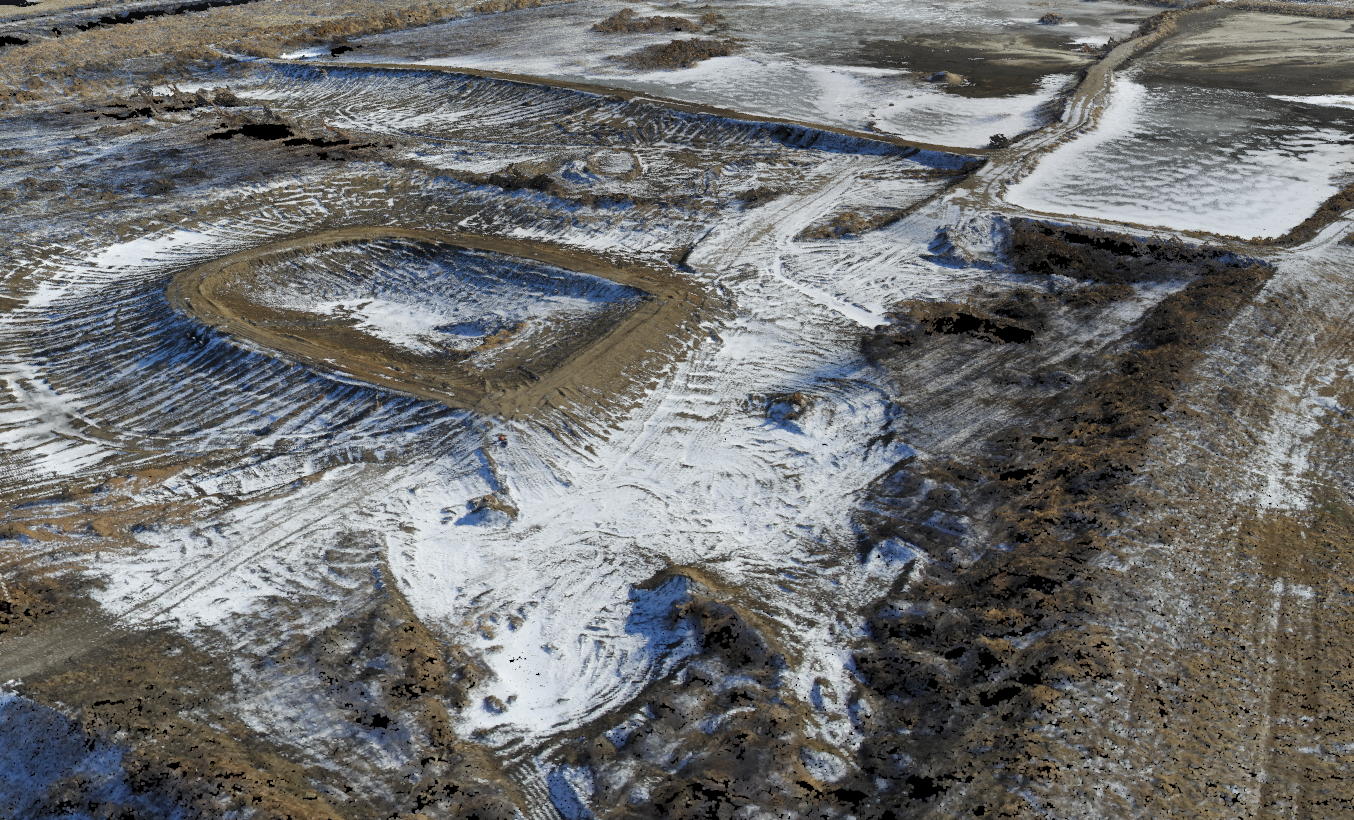

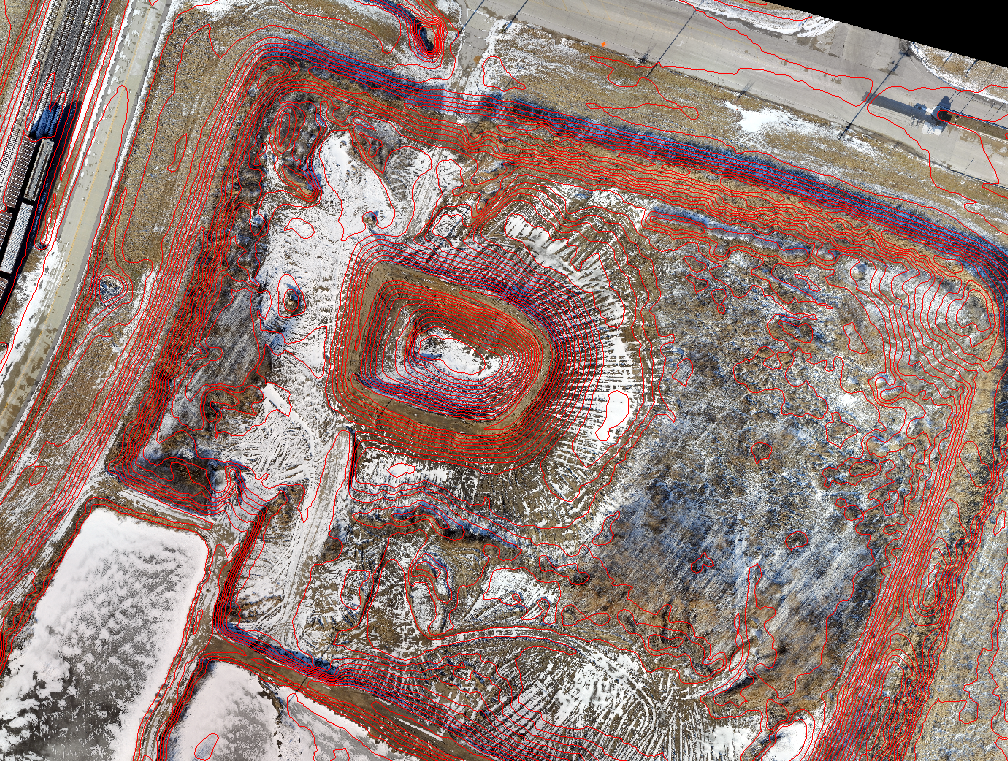

Traditional survey methods would require the use of a robotic total station or GPS to shoot a grid of elevation correct points. At a minimum, a 50’ x 50’ grid for a 60+ acres site such as this one would have required over 1,000 individual shots with multiple setups. Our drone easily captures many more data points, resulting in a much more detailed model of the site’s elevation at a fraction of the time. These minimum 1,000 shots would not have taken into account all of the spoil piles or trenches, and in order to maintain accuracy, we would have had to follow the natural breaks in the site, significantly adding to the amount of shots. Our UAS Survey method allowed our team to capture all the requested topographic information into a 3D model without the need to have crews walk the project site. By combining drone data with ground control points, we made sure that the data maintained a high degree of accuracy and provided an as-built model in the same coordinate system as the design data. Once combined, the as-built model could be compared against the pre-design existing surface to create a volumetric comparison of total earthwork. Horner & Shifrin staff created a bare earth data model for conversion to into an electronic format suitable for incorporation into America’s Central Port existing model(s). The platform provides us with an opportunity to verify field conditions and complete an analysis that would have otherwise taken much longer and been much more expensive.